To support our metallurgical testing business we also conduct Quantitative Xray Diffraction for our mineral processing clients.

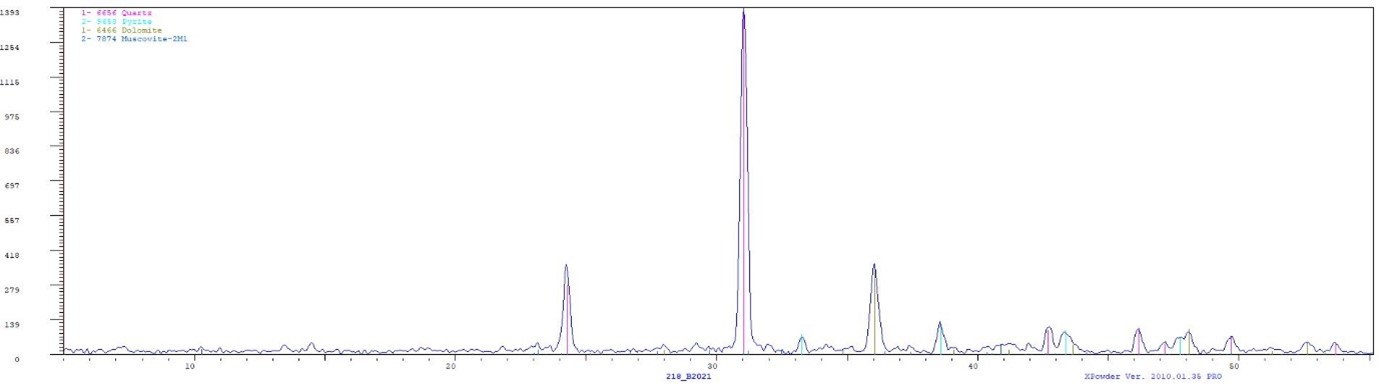

Xray diffraction allows the identification of mineral species (as opposed to elements) by the indirect measurement of the lattice spacing of the minerals present. Once the minerals are identified they can also be quantified based on the intensity of the peaks present. In the trace presented above the minerals identified are quartz, pyrite, dolomite and muscovite. It is important to note that XRD and QXRD are not overly sensitive detection techniques and once minerals present are less than 5%, detection suffers, and below 1%, it is extremely difficult if not impossible, to determine what the mineral present would be.

The minimum amount of sample required for QXRD is 1g. Sample preparation includes pulverising and screening over 150 micron screen. A subsample is loaded into a Olympus BTX-III XRD machine and exposed for 120 cycles. The instrument uses transmission geometry to analyse samples. The resulting XRD pattern is analysed by a combination of the programs SwiftMin and XPowder; which identifies phases in a sample by comparing them against known minerals from the American Mineralogist Crystal Structure Database (AMCSD). Supplementary information such as location specific data, geological description, analytical chemistry etc. supplied by the client will also be used to identify the minerals present. Subsequent to this, quantification of the minerals present is determined using Siroquant V3.0 software.

QXRD 24 hour turn around time

$400.00 for a 24 hour turn around time on a pulervised sample. Additional charges will apply for

sample preparation of a non-pulverised sample.

We will beat any price!

All you need to do is let us know what you are willing to pay and we will let you know if we are prepared to do the work.